WU2O piHPSDR Controller Unit

Updated 25 January 2017 (Originally

published September 2016)

This page was originally published in

September of 2016. Since then a lot has been learned, the software has

improved quite a bit, and built-in, local

audio capabilities have been added.

Why Build A Controller: The Vision

A piHPSDR controller is not something

I ever think of using for serious work. I

have a big, powerful computer with triple displays for that sort of

thing. The big computer has the necessary poop to run digital mode

software, loggers, and to

utilize all of the amazing powers of our radios. But the piHPSDR rig

has enough power to make it easy to envision

sitting in my favorite easy chair, the little controller propped on the

side table, feet up, drinks and snacks handy, maybe a football game up

on the big screen, and be able to casually work some DX or rag chew.

Anyhow, that's my vision and I'm sticking to it, as is plainly evident

;-)

This vision is getting closer and closer to reality. In September

the controller only had the most vestigial capabilities, and executing

a QSO was very problematic. Now, as of late December, one can have

perfectly serviceable phone QSOs with it and operation is quite stable

and reliable. There is even a three band audio equalizer for receive

and transmit. While there is a lengthy list of things to take for

granted in PowerSDR that are still missing, most notably split, freely

adjustable passbands, VOX, leveler, compressor and, of course,

PureSignal, no doubt these features are coming down the road. As these

features arrive, transmit audio quality, the hallmark characteristic of

openHPSDR architecture radios, will continue to improve. It is my hope

that eventually people will have to ask me on the air whether I'm using

a piHPSDR controller or a full size PC. If you are reading this in,

say, June of 2017, certainly things will have changed dramatically by

then.

Do you want to build your own controller? I bet you do! Even in thick

client form, the entire idea

remains quite compelling. Not only is it

fun to use, it's a quick and easy build. It

requires mostly mechanical fabrication skills and a little Linux savvy.

Material costs hover in the $350 range with built-in audio, a far cry

from the $1200 Maestro. And the future promise of using the controller

in a client-server role is, of course, the Holy Grail.

John Melton's (GO0RX) recent work on

piHPSDR,

his

presentation

at the 2016 Friedrichshafen ham radio conference, and Apache Labs

announcement of a

piHPSDR Controller Unit, was sufficiently

intriguing to motivate me to make my own piHPSDR controller unit.

There is obviously tremendous interest in this sort of thing. Indeed,

one might even say there is a bit of "Maestro envy" in the openHPSDR

community. The Flex

Maestro

being, of course, a "knobified", stand-alone, thin client controller

for the Flex series of client-server architecture software defined

radios (SDRs). However, before anyone gets too excited, there are a few

things to remember:

- openHPSDR architecture is still in "thick client" form and

thereby requires a fast, reliable, low latency connection to the

radio hardware. You might get Wi-Fi to work, and you might not. You

definitely won't be taking this thing to a hotel room with you and

using it over the internet at this time.

- John is a "one man band" and the software is in a constant

state of evolution. Hence don't expect to find all the features of

PowerSDR with every

bell and whistle possible when riding the bleeding edge of development

with your home brew piHPSDR controller unit.

- The Pi 3 processor is by no means an i7. Again, this will

necessarily limit what this unit can do in thick client form. Someday,

when the openHPSDR architecture evolves to client-server form, then the

sky will be the limit, but that day is not today.

That said,

current CPU usage on the Pi 3 is only in the 25% range. Clearly there

is plenty of poop left to implement PureSignal and more, and the Pi 3

remains a surprisingly capable platform for SDR use, particularly with

the efficiency with which John's code runs.

Design Notes

In developing my design I wanted something clean, compact, simple to

build, inexpensive, and requiring no printed circuit card development.

Obviously the design needed to include the four rotary encoder

controls, as that is the

signature design element. However, I intentionally did not include the

eight hardware switches, as I did not find that the soft keys on the

touchscreen display take up too much room. In fact, it seemed that the

soft keys on the touch display were more ergonomically pleasing.

However, now that I've got some operating time under my belt with this

controller, I do often wish for a PTT button. Nevertheless, I am

holding off on installing one until such time as VOX becomes a feature

of the software. I suspect that will be sufficient. Besides, leaving

out the eight buttons saves a ton of fussy measuring, drilling,

wiring and whatnot. Just try to get those eight buttons aligned in a

perfectly straight row without some milling equipment--good luck!

Speaking of luck, I found that the dimensions of the Smarticase

Pi/touchscreen enclosure and a Hammond sloped instrument enclosure

matched exactly. It was like they were made for each other.

In terms of encoder selection, there are a great many to choose from. I

wanted them to be panel mounted, not printed circuit board mounted.

Cost was definitely a consideration, otherwise I would have selected

all optical encoders, as nothing feels like a really well made optical

encoder. However, only the tuning wheel got an optical encoder, the

remaining encoders are the very inexpensive Bournes units.

Knob selection was very important. Cheap knobs that don't fit would

ruin the entire aesthetic. The aluminum knobs specified are a bit

pricey, but they really make the design shine!

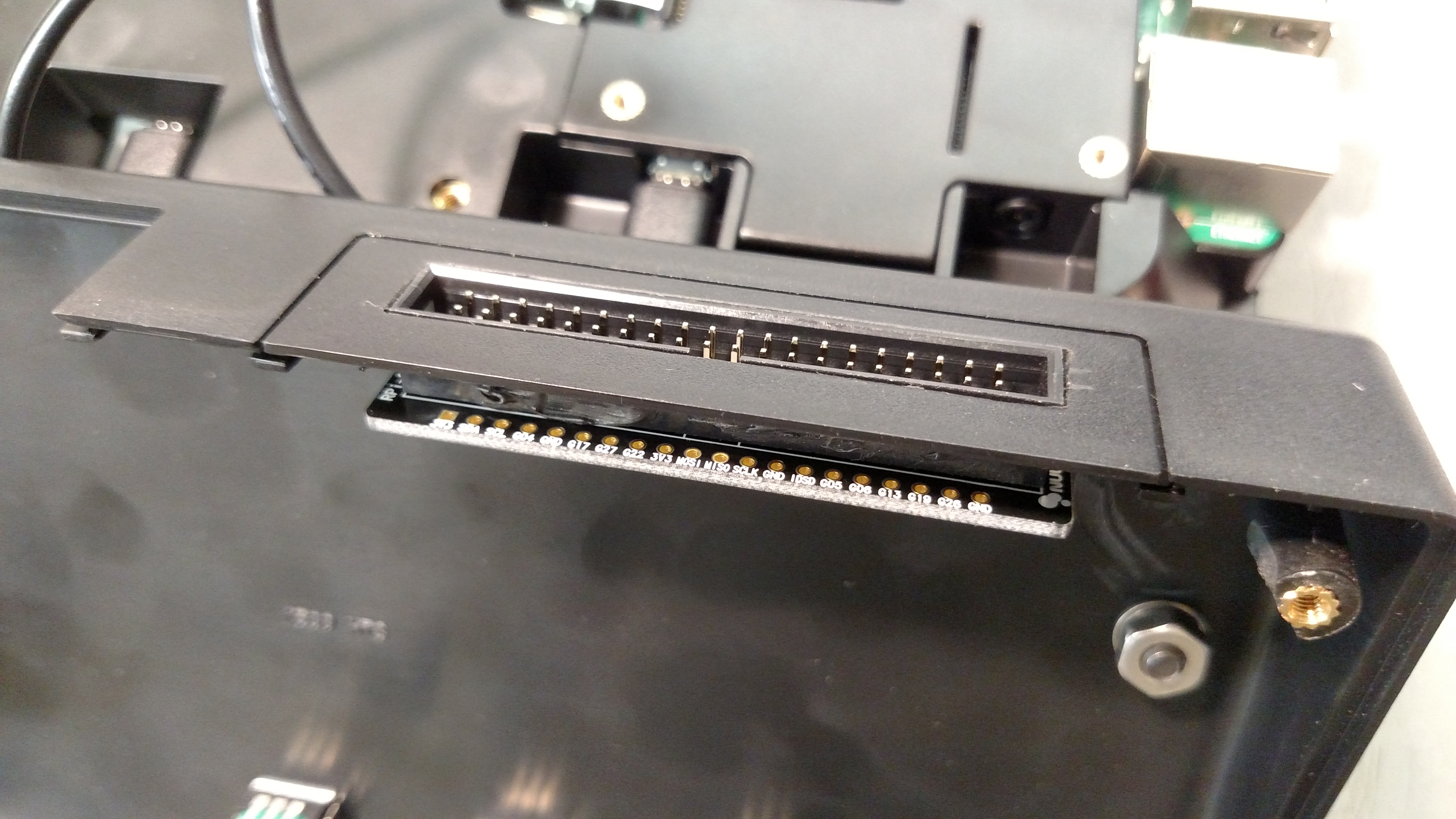

To simplify wiring, I chose from one of the many so-called Raspberry Pi

"cobbler" kits. These kits provide a nice little printed circuit board

and connector that make connecting to the Pi GPIO connector very easy.

In terms of power supply requirements, the Pi, display, USB audio

interfaces (see below) and whatnot draw only a total of 1.1A going full

blast while running piHPSDR. So the 2.5A wall wart

Raspberry Pi power supplies would seem to be OK with a good cable. I

suspect that most people experiencing problems are using USB cables

with 28AWG conductors in them. If you see a yellow lightning bolt on

the top right portion of your display, it means the Pi has detected an

under-voltage condition. Do a little research, and buy carefully. There

are many cables out there with 20AWG conductors in them and those will

work much better. I chose to go the overkill route since it is not very

expensive. Therefore a 10A supply from Adafruit with a barrel to

microUSB adapter was specified.

For storage, a 32GB SD card was a

no-brainer as storage is cheap, so no point in under-specifying that.

Finally, the design choices associated with obtaining local audio

output from the Pi were surprisingly complex. Initially I tried the

tip-ring-ring-sleeve (TRRS) audio/video connector output from the Pi.

Unfortunately, it turns out that the audio quality from this interface,

even when properly connected to an external amplifier, is quite poor,

with a bad noise floor. Apparently this is a known issue with this Pi

interface. Although some Pi's are OK in this respect, mine, like most,

was not. Therefore I chose to use an inexpensive USB audio interface. I

wanted good volume and spent some time researching various small

amplifier boards and speakers. To that end I chose a particular, 5V

powered, small amplifier board that got good reviews on eBay. I chose

the speakers more for looks than anything else! I wanted the speakers

to be on the top surface for best fidelity and volume and I did not

want to engineer speaker grills. So I chose a small speaker from Dayton

Audio that "looked good". As it happens, they also sound darn good as

well!

Material Requirements

The design that I implemented depends very strongly on the availability

of a particular Raspberry Pi 7" touchscreen housing from Smarticase. Of

all of the components on the bill of materials, that is the only one

that I would be worried about in terms of its continued availability.

The rest of the parts are "meat and potatoes" items from stable

suppliers.

| Item |

Manufacturer |

Mfg Part Number |

Supplier |

Supplier Part Number |

Qty |

Price Each |

| Touchscreen/Pi enclosure |

Smarticase |

SmartPi Touch w/microUSB

Y-cable |

See mfg. site |

SmartPi Touch |

1 |

$29.99 |

| Encoder enclosure |

Hammond |

1599HTSBK |

Mouser |

546-1599HTBSK |

1 |

$13.24 |

| #8x3/4" flathead machine

screws |

N/A |

N/A |

N/A |

N/A |

4 |

<$.25 |

| #8 flat washers |

N/A |

N/A |

N/A |

N/A |

4 |

<$.10 |

| #8 lock washers |

N/A |

N/A |

N/A |

N/A |

4 |

<$.10 |

| #8 nuts |

N/A |

N/A |

N/A |

N/A |

4 |

<$.10 |

| Processor |

Raspberry Pi |

Model 3 B |

Various |

Follow this link |

1 |

$35.70 |

| 7" touchscreen display |

Raspberry Pi |

7" Touchscreen LCD

Display |

Amazon |

Follow this link |

1 |

$69.99 |

| GPIO cable & breakout

board kit |

Nulsom |

RPi GPIO Cobber |

Amazon |

Follow

this link |

1 |

$8.95 |

| 10A 5V power supply |

Adafruit |

658 |

Adafruit |

658 |

1 |

$25.00 |

| MicroUSB to 2.1 barrel

adapter cable |

Adafruit |

2727 |

Adafruit |

2727

|

1 |

$1.95 |

| 32GB MicroSDHC card with

adapter |

Samsung |

MB-MP32DA/AM |

Amazon |

Follow

this link |

1 |

$11.50 |

| 24 PPR/24 detent encoder

w/switch |

Bournes |

PEC11R-4215F-S0024 |

Mouser |

652-PEC11R-4215F-S24 |

3 |

$1.63 |

| Small knob |

TE Connectivity |

KN770B1/4 |

Mouser |

506-KN700B1/4 |

3 |

$10.10 |

| 120 PPR/no detent optical

encoder |

Broadcom/Avago |

HRPG-ASCA-13C |

Mouser |

630-HRPG-ASCA-13C |

1 |

$30.90 |

| Large knob |

TE Connectivity |

KN1751BS1/4 |

Mouser |

506-KN1751BS1/4 |

1 |

$34.96 |

| Speaker |

Dayton Audio |

CE32A-8 |

Various |

N/A |

2 |

~$10.00 |

| USB Audio Sound Card

Adapter |

Sabrent |

AU-MMSA 2.1 |

Various |

N/A |

1 |

~$7.00 |

| Audio Amplifier Board |

uxcell |

PAM8403 |

Amazon |

Follow this link |

1 |

<$3.00 |

| 1/8" stereo mini phone

plug |

N/A |

N/A |

Various |

N/A |

1 |

<$1.00 |

| USB Left Angle A-to-A

Cable |

UCEC |

N/A |

Amazon |

Follow this link |

1 |

<$3.00 |

| Hookup wire (28 to 22AWG

will work) |

N/A |

N/A |

N/A |

N/A |

AR |

|

| Solder |

N/A |

N/A |

N/A |

N/A |

AR |

|

| Heat shrink tubing

(various diameters) |

N/A |

N/A |

N/A |

N/A |

AR |

|

| 3M high bond double sided

tape |

N/A |

N/A |

N/A |

N/A |

AR |

|

| Black RTV adhesive |

N/A |

N/A |

N/A |

N/A |

AR |

|

*AR=as required

Construction Details

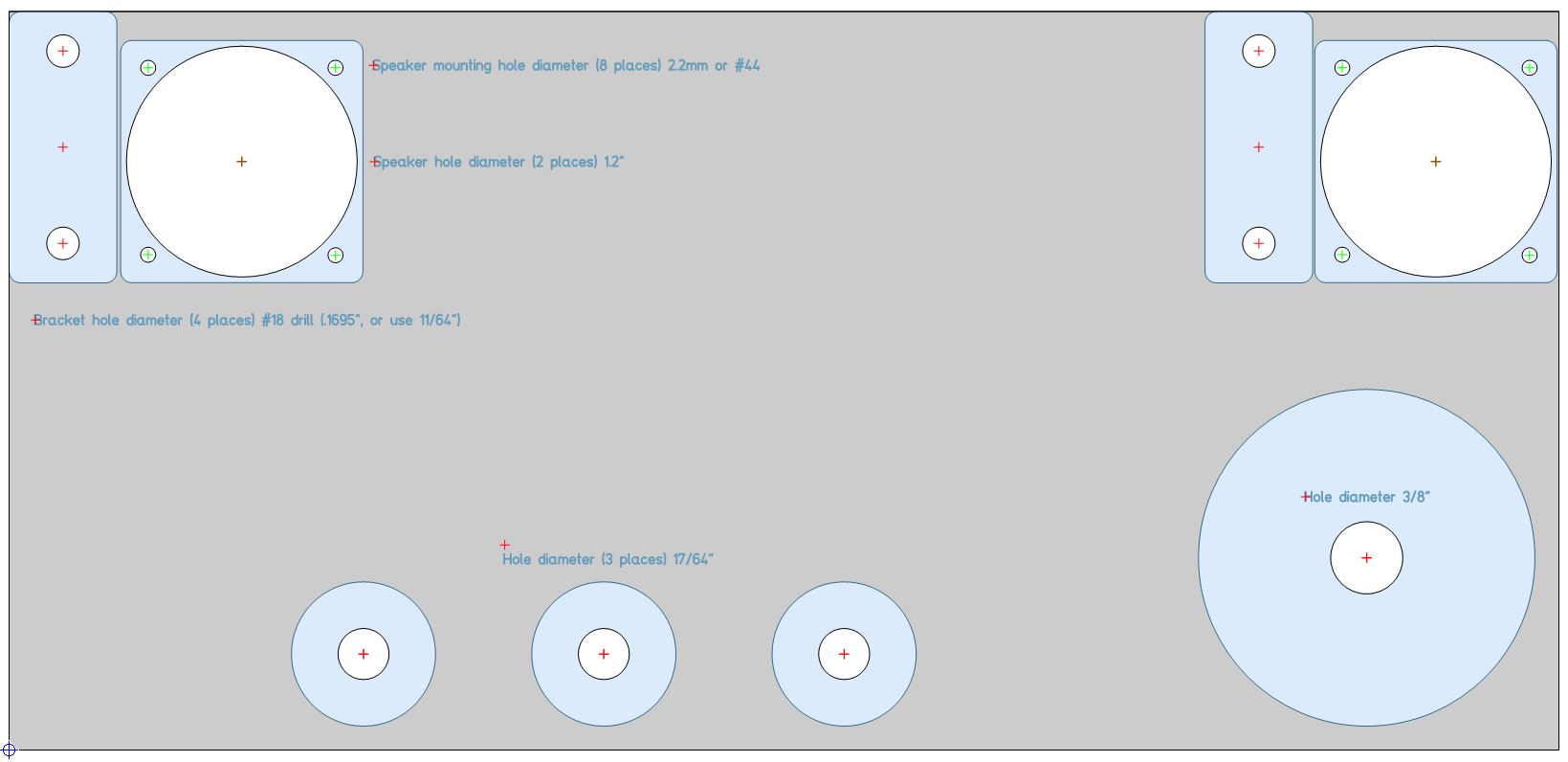

Drilling the Top Panel

Download and print the

drilling

template.

Print at 100%. Cut out the template and tape it to the top surface of

the Hammond enclosure. If printed at 100% it should match the top inlay

surface of the enclosure. Mark the reference points with a scratch awl

or other pointed tool. Drill holes sized in accordance with the

drilling template. The plastic on the Hammond enclosure is very soft. I

had best results by drilling at very low speeds and by drilling the

holes in steps, starting with a 1/16" pilot hole and moving up through

some intermediate size drills before drilling at the required final

diameter. How accurately these holes are made makes the difference

between a good looking product and a not so good looking product. For

the speaker openings I used a large step drill bit.

Undercut the Mounting Boss

The rear left mounting boss on the top panel will interfere with the

fastener in the corner that attaches the Smarticase hinge. Use a Dremel

or similar tool to carefully machine away the mounting boss plastic

such that a nut and washer can be placed in that area.

Attach the Smarticase Hinges to the

Top Panel

Not much to say here. Screws, washers, nuts. Just make sure the hinges

are oriented so that the hinge fasteners insert from the left and right

so that they are easy to access. Test fit the Smarticase after the

hinges are mounted, just to see if any adjustments are in order. I

managed to find these really nice, black oxide coated, socket flathead

screws at the local hardware store. They are sexy!

Hand Fit the Speakers Into the Top

Panel

This can be very fussy work to make it look good, depending on how you

decide to do it. In my case I did not want to engineer or fabricate a

set of speaker grills. Therefore I chose to front mount the speakers

into the enclosure. To accomplish this required some delicate hand

filing of the enclosure and fitting of the speakers. In retrospect it

might have been easier to fabricate those speaker grills, and I have

since obtained some metal grill material that I may use in another

version. Nevertheless, the speakers do fit quite nicely next to the

display hinges, and are reasonably well protected in those spots. You

will need to find some 2mm fasteners and hardware to fit through the

speaker mounting holes. I actually found some at my friendly local

hardware store, however I may order some black oxide coated hardware

off of the internet just to make it look a bit sexier.

After fitting the speakers, remove them and lay them aside as you will

not want to install them until you have soldered the leads to them.

Also, by assembling the speakers last they are less likely to be

damaged.

Assemble the Touchscreen and Pi Into

the Smarticase

Assemble the Touchscreen and Pi Into

the Smarticase

For now don't use the supplied screws to secure the Pi, just let the

door secure the Pi and, optionally, add those screws when all is done.

The reason for this is that otherwise the Pi can't be lifted out to

insert the SD card. And don't use the jumper wires to power the

touchscreen. Instead plan to use the microUSB Y-cable that comes with

the Smarticase kit to power the Pi and the touchscreen.

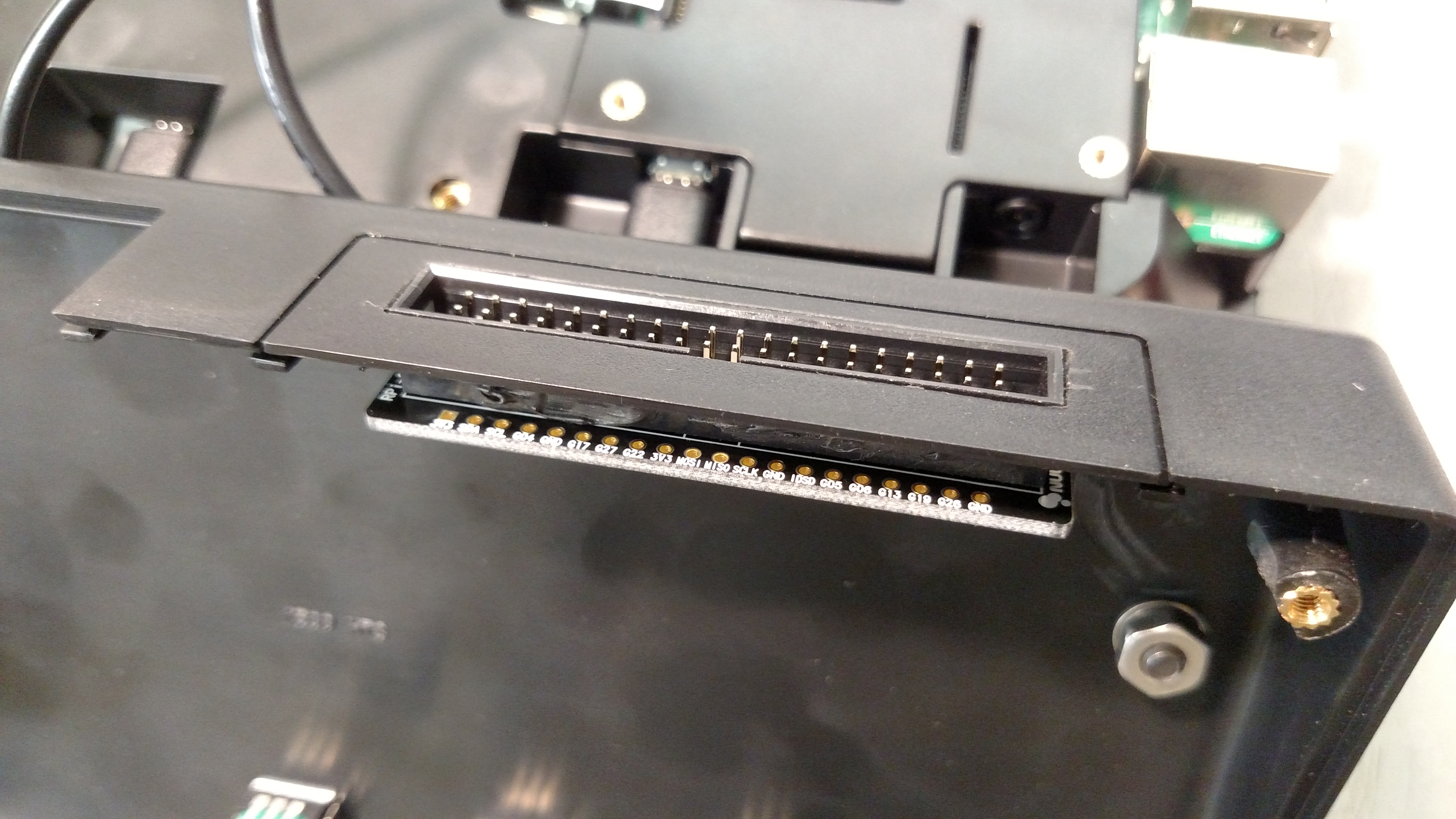

Solder the Cobbler Board to the

Cobbler Connector

Solder the Cobbler Board to the

Cobbler Connector

Temporarily assemble the Pi, GPIO cable, cobbler connector panel and

cobbler board. Check the mechanical orientation and fit of everything.

Power up the Pi and, with a meter, check that 5V, 3.3V and ground are

in showing up on the labeled places on the board. This will help avoid

the very annoying mistake of soldering on the board in the

wrong orientation. Once you are 100% happy with the orientation of the

board, solder all of the pins to the connector.

I am so embarrassed I took that photo before cleaning the flux off!

Fabricate the Cobbler Kit Connector

Panel

The Hammond enclosure comes with these nice little removable panels on

the back. I mounted the cobbler kit connector into the left side panel,

aligned with where the GPIO connector is on the Pi when it's mounted in

the Smarticase enclosure. This is probably the most difficult part. I

wanted mine to be as good as I could get it, so, after drilling a

length

of 1/4" holes to make the beginnings of a rectangular hole, I spent a

lot of time hand filing that hole to be rectangular. Most people will

probably just go

to town with a Dremel. Your choice! Once the hole is made, lay the

exterior surface of the panel down on a flat surface, drop the cobbler

kit connector into the panel hole with the key oriented down towards

the bottom edge of the panel and glue it together with some RTV. Do not

get RTV in the keying area or on the pins. Let it dry overnight. You

will be tempted to fuss with it that day, but that will just result in

the assembly being damaged.

Assemble the Encoders into the Enclosure

Align them as you prefer for doing the wiring. You can follow my

example shown below if you desire. The mounting nuts do not require a

lot of force. These are small devices made out of inexpensive pot

metal, so go easy on them. Indeed, the Bournes encoders are, dare I say

it, cheap, and easily damaged. Again, go easy.

Assemble the Knobs onto the Encoders

You will need a 1/16" Allen wrench. On the small knobs, align one of

the set screws with the flat on the shaft, tighten, loosen just a

little, and let the knob fall until the set screw is resting on the D

section floor. This will ensure that all knobs are the same height and

have enough clearance to the enclosure surface. On the large knob just

let the knob fall all the way to the bottom of the shaft. Make certain

the knobs are not sitting so low they drag on the enclosure or, on the

Bournes encoders, hit the enclosure when pressing down to activate the

momentary switch action. Tighten all of the set screws, of course.

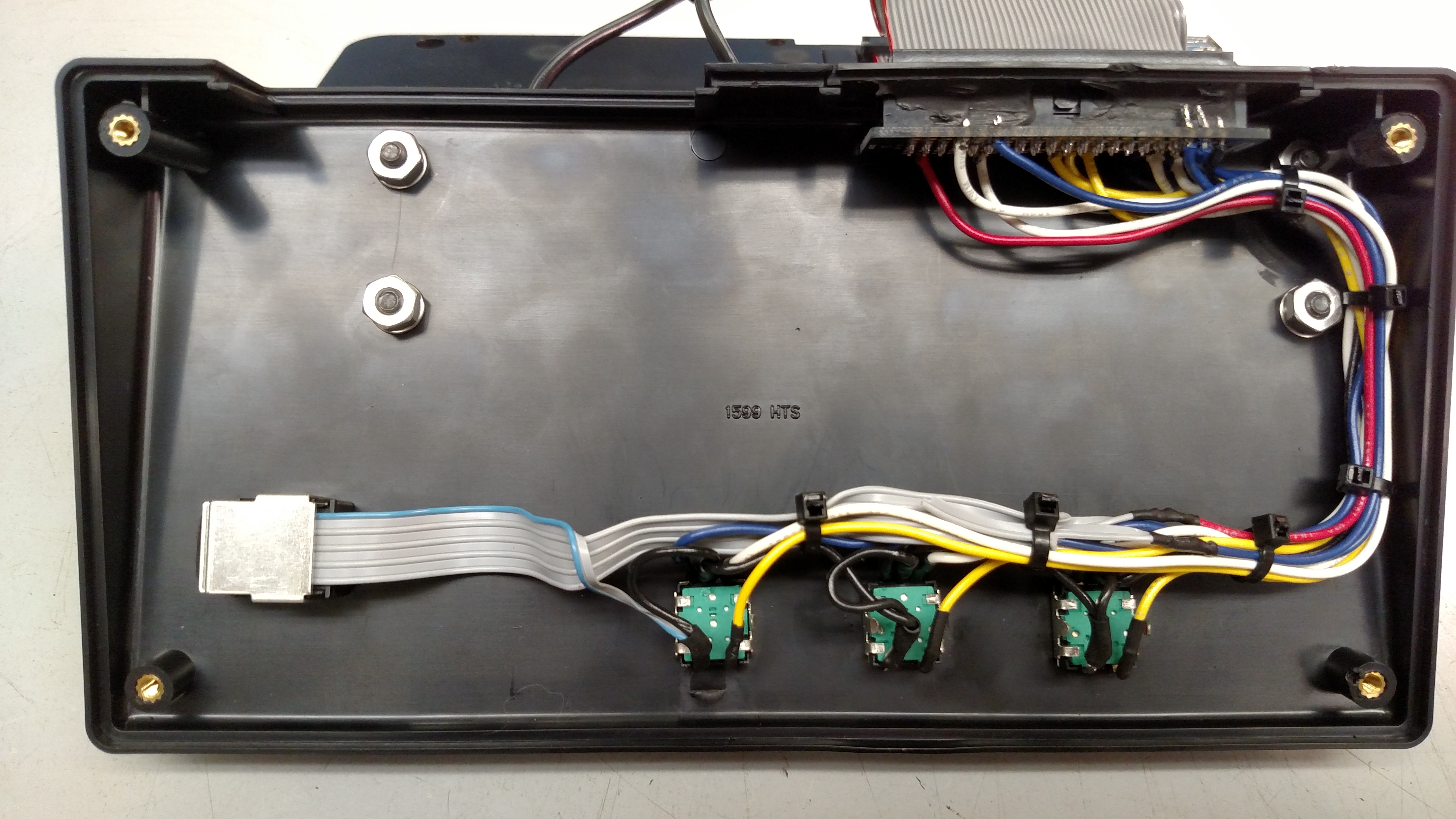

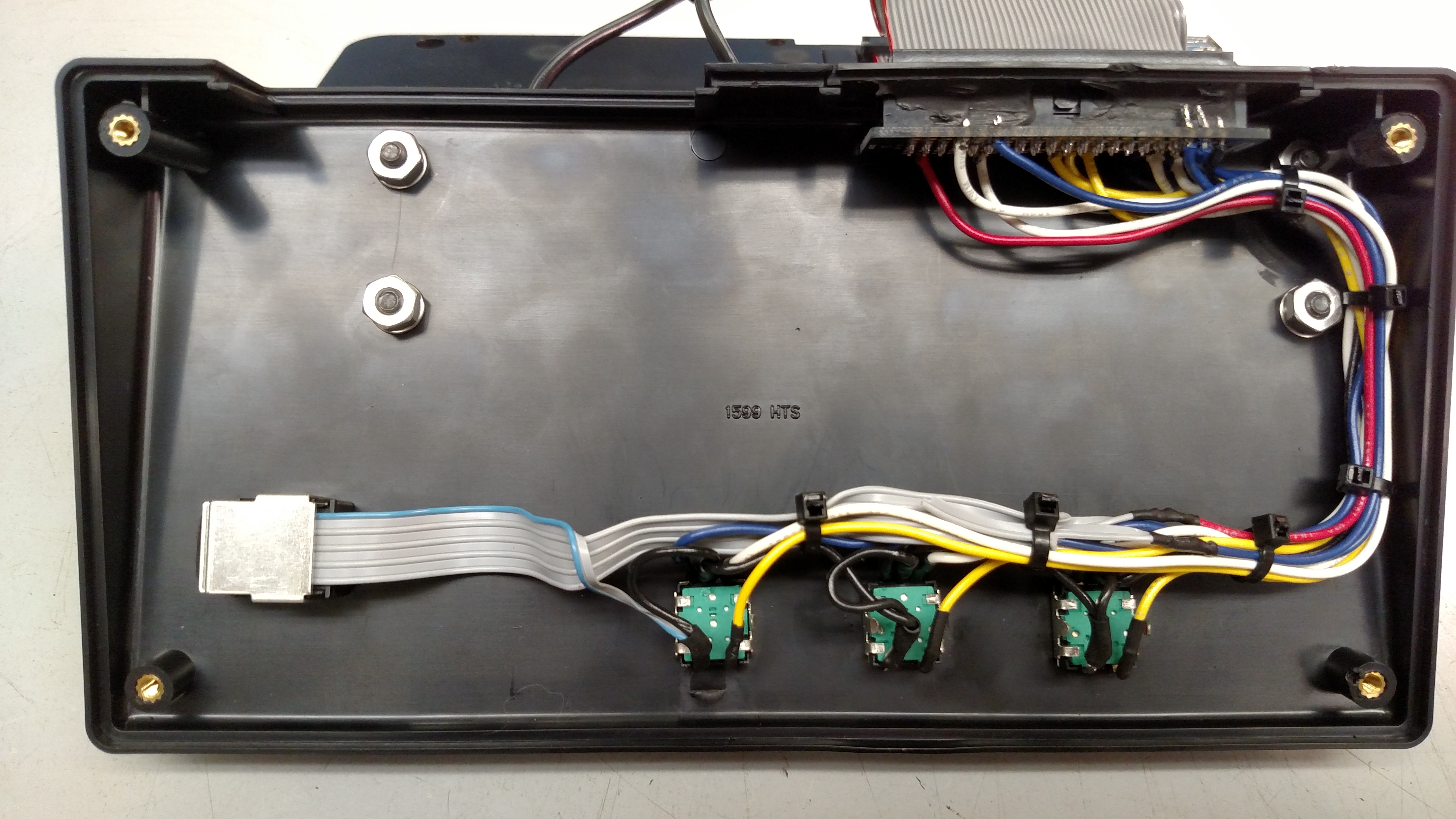

Wire the Encoders to the Cobbler Board

Refer to the manufacturer's data sheets, available from Mouser, for the

pinouts of the encoders. I simply daisy chained a single ground wire

all the way over to the cobbler connector. Both ground pins on the

encoders need to be wired. If you accidentally reverse the A and B

lines it's no big deal, you can reprogram that in the piHPSDR software.

Only the Avago optical encoder needs a 5V connection.

The photo below shows the unit wiring before I added the speakers,

which is handy for clarity's sake. The wires are routed around the edge

of the assembly so that the

center area is left open for the audio components.

Be very careful with the soldering iron. If it touches the Hammond case

the case will melt instantly. Similarly, if you use shrink tubing and a

heat gun, go easy with the heat on the case. If you are very paranoid,

you could actually assemble the encoders into something temporary so

that they have the same orientation, like a scrap piece of plastic or

cardboard, wire them, then transfer the entire assembly back into the

case. In fact, if I build another one, that is exactly what I am going

to do.

Wiring is as shown in the table below.

| FROM

|

TO

|

| ENCODER

|

PIN

|

GPIO

CONNECTOR PIN # |

GPIO

SIGNAL |

| VFO |

+5V |

4 |

+5V |

| VFO |

A |

11 |

GPIO 17 |

| VFO |

B |

12 |

GPIO 18 |

| VFO |

GND |

Note 1 |

GND |

| AF |

A |

37 |

GPIO 26 |

| AF |

B |

38 |

GPIO 20 |

| AF |

C |

Note 1 |

GND |

| AF |

1 |

Note 1 |

GND |

| AF |

2 |

22 |

GPIO 25 |

| AGC |

A |

40 |

GPIO 21 |

| AGC |

B |

7 |

GPIO 4 |

| AGC |

C |

Note 1 |

GND |

| AGC |

1 |

Note 1 |

GND |

| AGC |

2 |

26 |

GPIO 7 |

| RF |

A |

35 |

GPIO 19 |

| RF |

B |

36 |

GPIO 16 |

| RF |

C |

Note 1 |

GND |

| RF |

1 |

Note 1 |

GND |

| RF |

2 |

24 |

GPIO 8 |

Note 1: ground wires were daisy

chained from encoder pin to encoder pin and terminated

on GPIO connector pin #39 (GND). Other GPIO ground pins include 6, 9,

14, 20, 25, 30 and 34.

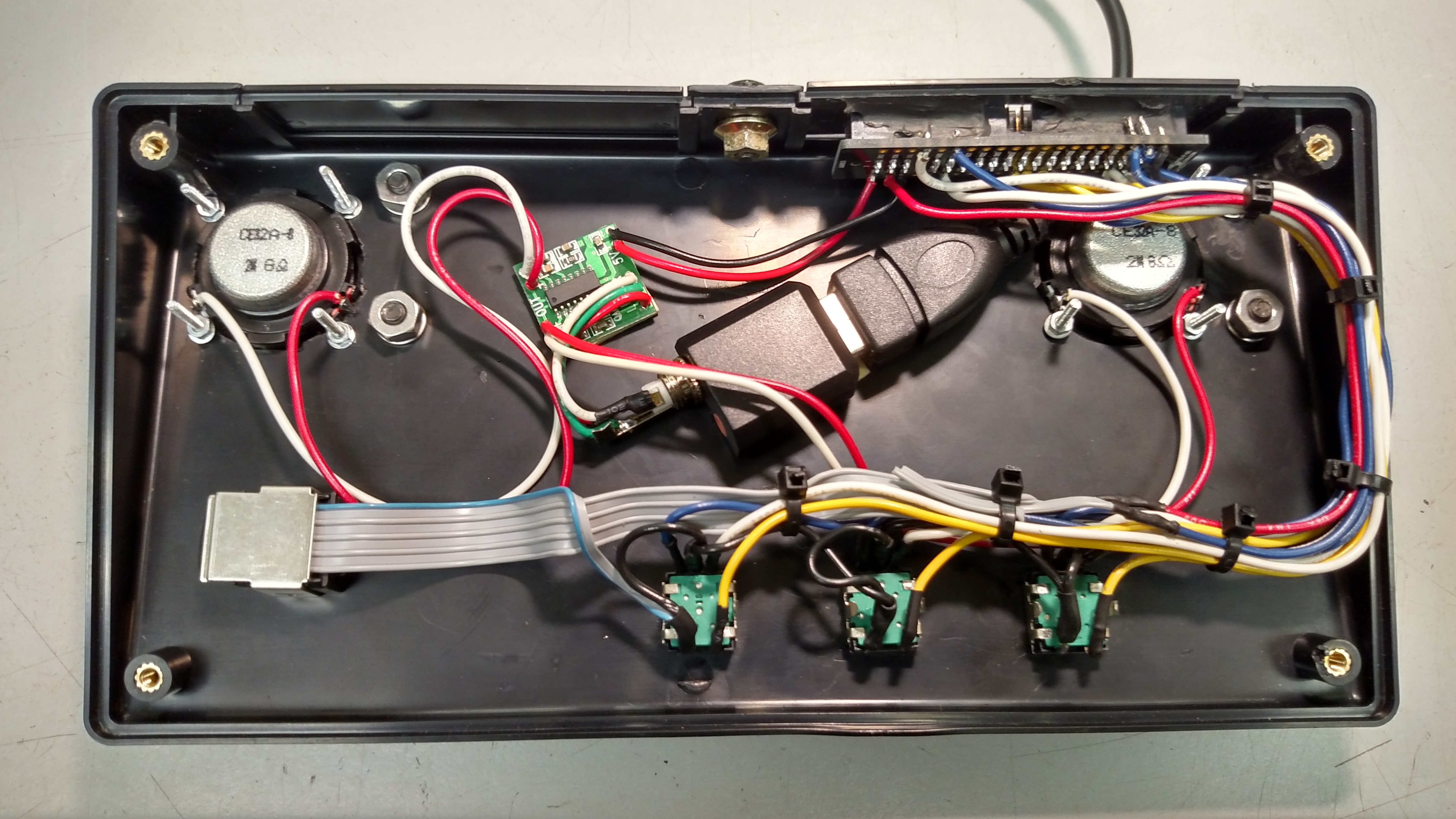

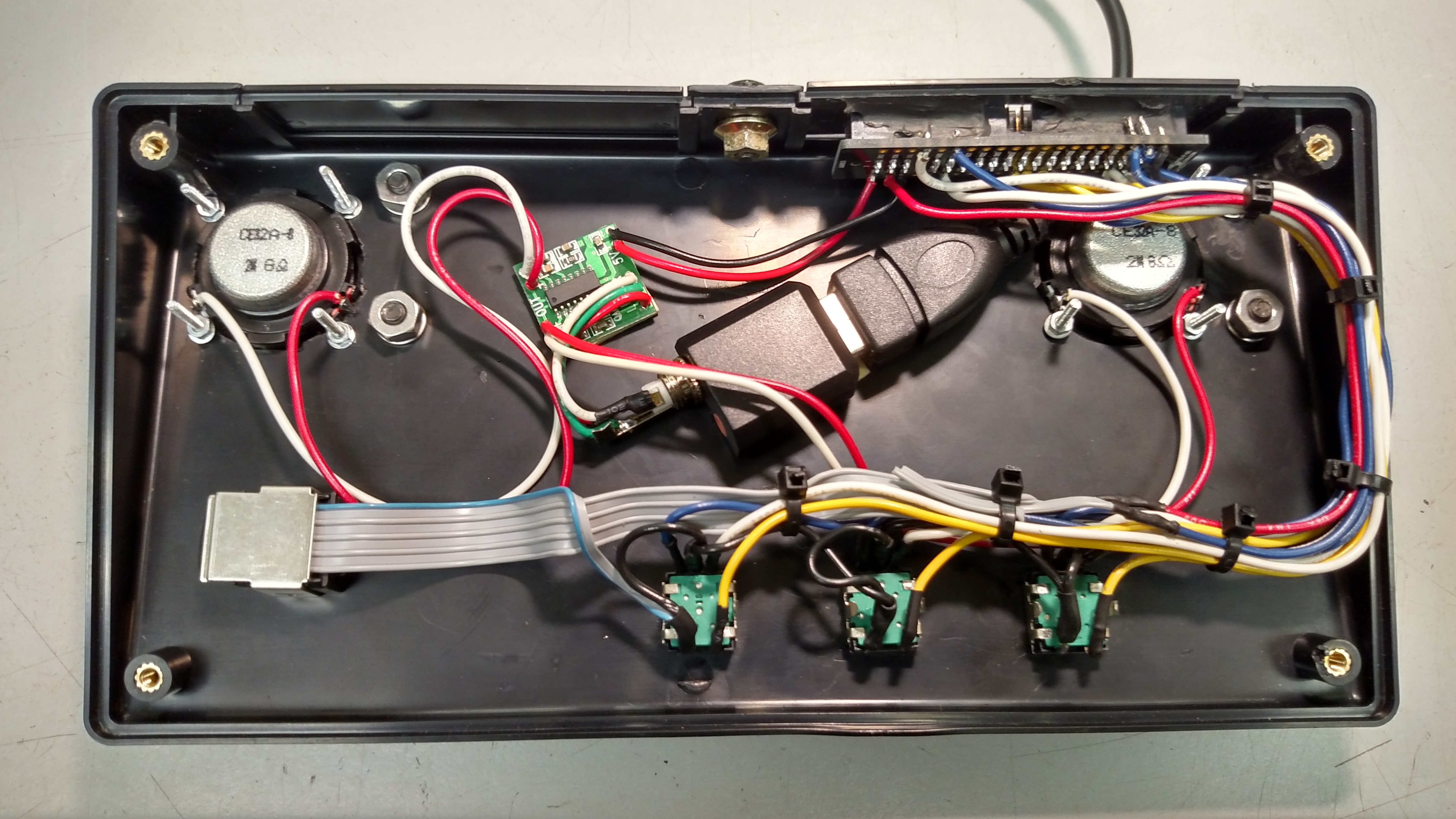

Assemble the Audio Components

Make a small notch in the case as shown to allow passage of the

left-handed, right-angle USB extender cable. The left-hand nature of

the connector is important so that it has a fair lead out from the USB

connector on the side of the Pi. If you make the notch just a little

small, it will hold the cable securely and not allow it to be pulled

out of the enclosure. Test fit the display as required to ensure you

have enough cable to reach the USB connector and for the display to be

able to be angled over its full range. (Note the screw on the back as a

future ground connection point--so far I have not needed to ground the

unit, though).

With the USB extender cable arranged as shown, secure it and the

Sabrent USB audio interface with some 3M double-sided, high bond tape

(or equivalent).

Solder speaker, power and input wires to the audio amplifier board.

Again, it is recommended to do this outside the enclosure on the bench

as the Hammond enclosure is quite heat sensitive. Also solder the 1/8"

mini stereo phone plug to the inputs wires: tip is left, ring is right

and shield is ground.

You can pull the cobbler board assembly out and away from the enclosure

to solder the 5V and ground wires from the audio amplifier to it.

Plug the stereo phone plug into the green jack on the Sabrent USB audio

interface. Secure the audio amplifier board into the enclosure with

some 3M double-sided, high bond tape (or equivalent).

Finally, solder the speaker wires to the speakers before mounting them

to avoid soldering iron heat damage to the enclosure, then assemble the

speakers into the enclosure. When soldering the speaker wires pay

attention to achieving the same polarity on both speakers. This way the

speakers will operate in phase with each other for best sound quality.

You might also, optionally, consider provisioning an 1/8" mini mono

jack on the rear of the enclosure, connected to the microphone input on

the Sabrent USB audio adapter. This way you could plug in a wired

microphone to use locally. I chose to forgo that approach for now, as I

prefer to use a USB headset when actually having a QSO.

Assemble the Smarticase onto the Hinges

Oh boy, now it's starting to look cool! You might consider modifying

the GPIO cable to be shorter. It is possible to disassemble and reuse

the IDC connector at one end. Carefully pry it off, then measure and

trim the ribbon cable. Be sure to leave enough cable so that the

display can hinge over its full range of motion. Then reassemble the

IDC connector, with the correct orientation of course, at the new end

of the cable. A bench vice makes a handy press for IDC connector

assembly. If you don't have a vice to squeeze it in I'm not sure I'd

try this. IDC connectors and ribbon cable are cheap and you can always

get some additional material and simply make a whole new cable later.

Don't forget to plug in the USB cable to the audio interface, too.

While not the

most flattering photographic angle, nevertheless in this photo you can

also see the Adafruit 10A 5V power supply and

2.1mm barrel to microUSB adapter cable. This attaches to the micro-USB

Y-cable to power the touchscreen and the Pi. Ten amps is plenty

for USB headsets, audio amplifiers, 802.11ac Wi-Fi dongles, and

whatever else might be added in the future for, as mentioned above, the

whole kit is drawing only about 1.1A as is.

Build, Install and Configure the pi

Operating System

Get the Pi and touchscreen running. There are plenty of websites to

hold your hand here. If you are not a Linux jockey, be prepared to

hack--er, I mean learn! Google and Youtube are your friends. However, I

will suggest a few hints and recommendations:

- An HDMI display is not needed. The latest version of Raspbian

will find the touchscreen right away if the touchscreen is properly

attached.

- Install MobaXterm on your PC first. That way you can just SSH in

for configuration and don't need to bother with attaching a mouse or

keyboard. Google "using MobaXterm with Raspberry Pi".

- Use straight Raspbian, don't bother with NOOBS.

Install piHPSDR

Follow John's instructions in the installation document precisely. It

can be found at

https://github.com/g0orx/pihpsdr/tree/master/release/documentation.

Configure piHPSDR GPIO Settings

When piHPSDR is started, it will first be necessary to press the button

to configure the GPIO settings. The three Bournes encoders will require

the pull-up

to be turned on, but not the Avago optical encoder. If any A and B

settings need to be swapped, this is

where it can be done. Be aware that the numbers shown are the GPIO

signal numbers, not the connector pin numbers.

This is also where the knobs can be rearranged. If you decide you want

to re-order the knobs on the front panel, just change the numbers here

to get what you want.

Test the Encoders and Encoder Switches

With piHPSDR up, running and connected to a radio, twist the knobs and

see what happens. As of December 2016, the AF knob will adjust the

audio volume and pressing its momentary switch will lock and unlock the

VFO. The AGC knob obviously adjusts the AGC level, pressing its

momentary switch will change the knob to RIT. The RF knob adjusts RF

drive and right now the switch doesn't seem to do anything.

If something isn't working right then things will have to be debugged!

Most likely there is a wire misplaced on the cobbler board.

Assemble the Bottom onto the Hammond

Enclosure

A few encoder pins may need to be bent or a few wires moved for

clearance. I put the supplied stick-on feet next to the fastener holes,

not over them, since I expect I will want to modify the unit in the

future.

If the entire assembly feels a little unbalanced, a few small lead

weights glued inside the front of the bottom part of the housing with

RTV will give it a little extra heft.

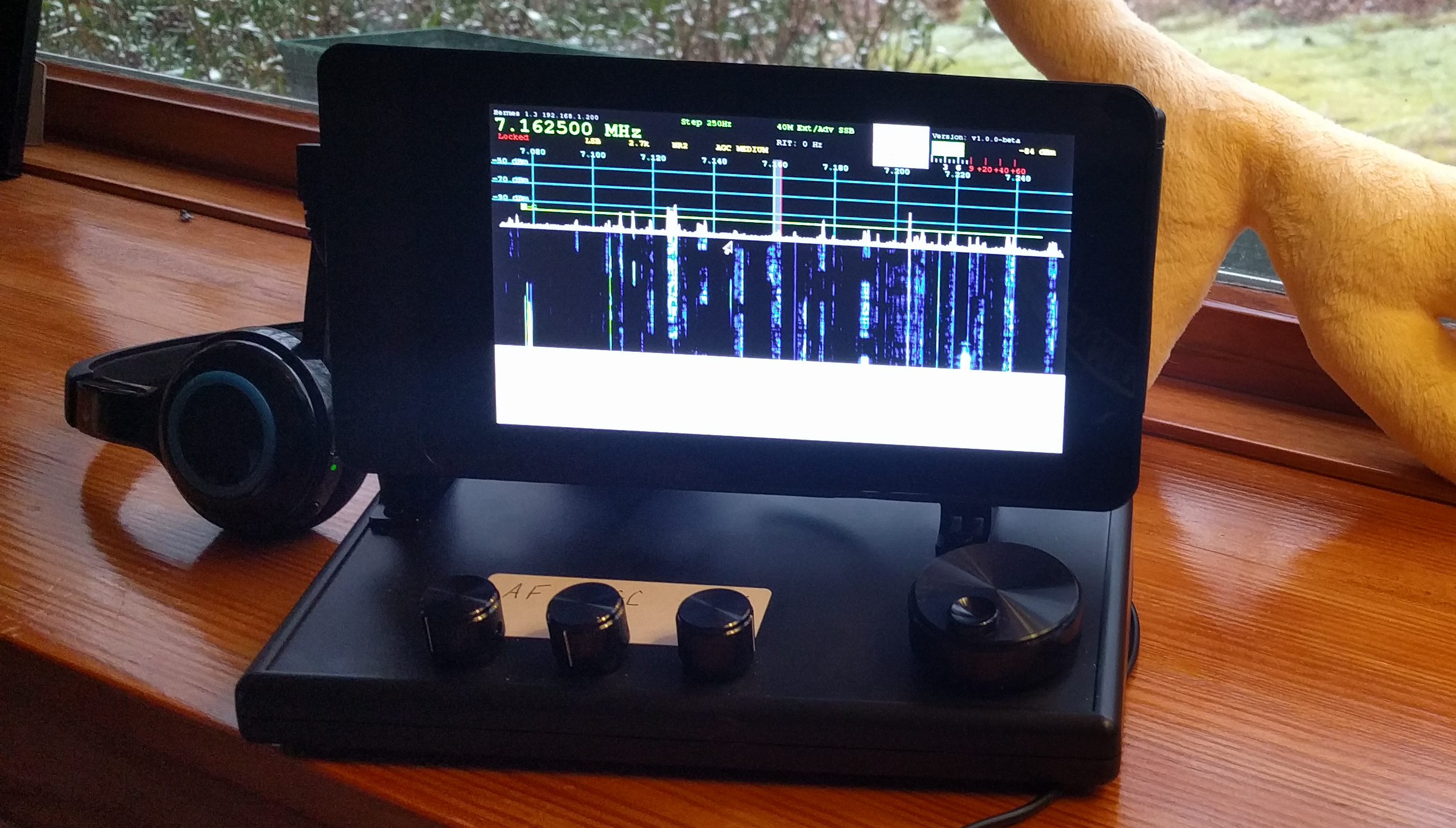

The Finished Result, Local Audio, and

Some Operating Tips

So there you have it, a nice piHPSDR controller with built-in, good

quality, local audio capability. Having the built-in USB audio

interface does not preclude the use of additional USB audio devices,

although currently piHPSDR will only let you use one at a time.

In the photo above you can see a Logitech H-800 wireless headset.

This headset works quite well with the Pi by means of its 2.4GHz

wireless USB dongle adapter. Although this headset is also Bluetooth

capable, Bluetooth on Linux, and Raspbian in particular, is not quite

ready for prime time! There is also a less expensive H-600 version. And

of course you can use essentially any wired USB headset on the market.

I've had very good luck, and very good signal reports, with a Microsoft

Lifechat LX-3000.

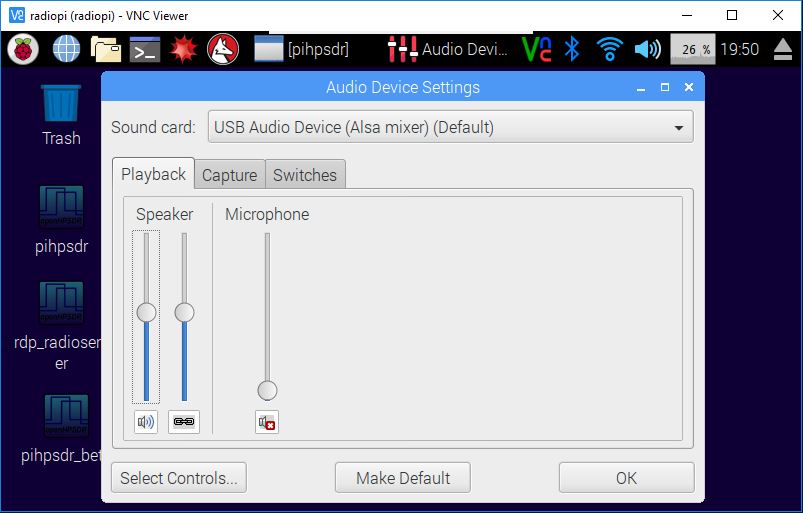

Local Audio Setup

In Raspbian, click on the Start Menu (the raspberry icon in the upper

left),

then Preferences, then Audio Device Settings. Choose the "USB Audio

Device" and make it the default. This will now allow the Pi to produce

all of its sounds through the Sabrent audio adapter and the Dayton

Audio speakers. Hit the "Select Controls" button, enable all controls,

and then set the Playback Speaker levels to 50% to start. Play some

Youtube videos or something to test your work.

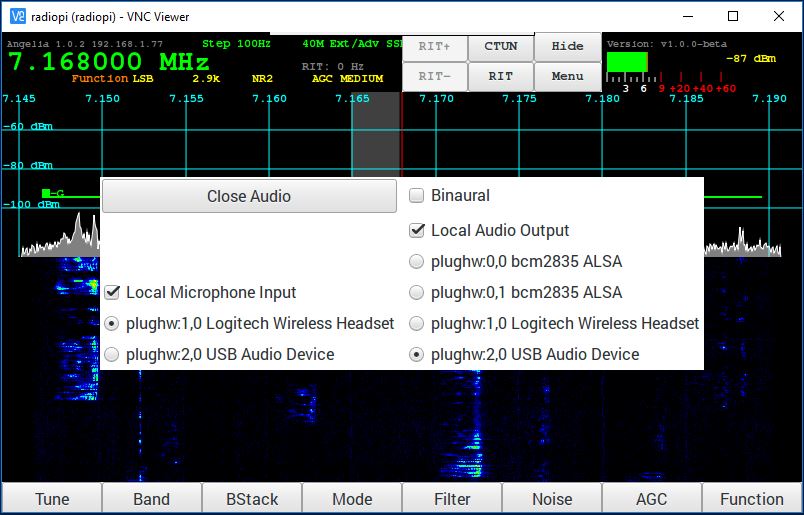

When using piHPSDR, obviously you

must select the audio interfaces you

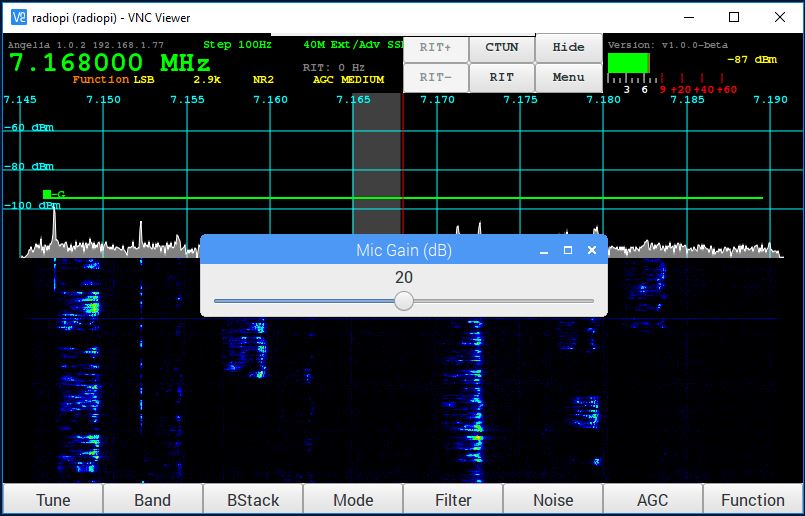

wish to use for receive and transmit in Menu > Audio. Be sure to

check the "Local" boxes as appropriate. I have found that with every

USB audio device I have tried the microphone gain wants to be at 20dB.

Even though this results in quite a bit of ALC indication, 20dB mic

gain has obtained the best on air signal reports. Obviously this will

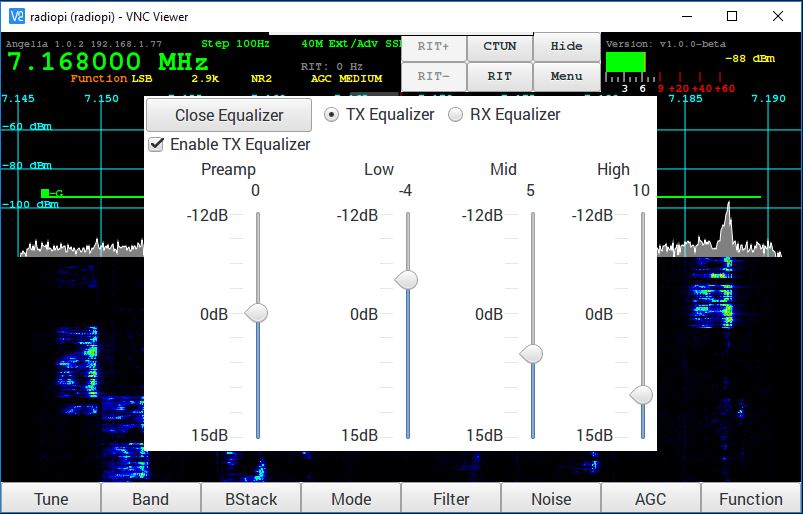

change as John implements more audio processing such as a compressor,

or a leveler, etc. I have also found that the USB audio sources

have benefited from a pronounced upward tilt in the equalization curve.

Watch your spectrum on the panadapter as you transmit and, as a

starting place, try to even out the energy content across the transmit

passband. As of December 2016, your transmit passband will be made

equal to the receive passband (filter) selected. The passband limits

are currently hardcoded, you can see what they are here:

https://github.com/g0orx/pihpsdr/blob/master/filter.c.

Finally, a word about latency. As of December 2016, latency in piHPSDR

is quite high. I have not measured it precisely, but it appears to be

on the order of 500mS. Using a Logitech H-800 wireless headset makes

this worse, as the 2.4GHz link of the headset adds another few hundred

milliseconds of latency itself. Certainly this can be expected to

improve as the code evolves.

Operating Tips

The number one thing that should be done before operating is to

calibrate the PA gain settings in piHPSDR. Without this being done it

can very difficult to obtain the desired performance from the radio

using piHPSDR. Be sure to go to Menu > PA and perform this

calibration. Use a dummy load, of course.

The method I recommend is to go into Tune mode and adjust Tune Drive to

be the value you will most normally operate at. If that is a barefoot

100W, set drive to 100. If that is 30W to drive an amplifier, then set

drive to 30. This way the calibration will be most accurate at this

drive level. With the drive set to your most used, nominal value, make

the adjustments in the PA Gain menu as required to obtain an RF output

power level that matches the commanded drive level.

Great Stuff: Other People's Work

Rick, N9HLL, and his interpretation of the project, with his own unique

encoder layout. Great work, Rick!

Doug, K3DAK, has built a version that uses 12VDC power and some

other neat touches. You can see many more detailed photos on how he

constructed it at his

imgur page.

Mike, K0JTA, went with silver knobs, a single large speaker, and very

cleverly used some printed circuit board material as a speaker grill.

He's also got a power switch, power LED, and brought out the microphone

input to his internal USB audio interface. You can read more about

Mike's build at his web site,

http://s3com.net/pihpsdr/page2.html.

If you have built a piHPSDR controller using my mechanical design, then

I'd love to receive a photo from you that I could add to this web page

to show off your work. As Rick did, no doubt many of you will have

slightly different arrangements of the knobs, etc., and it would be

great to show other ideas on control placement within the context of

the basic layout.

Future Projects: 802.11ac Wi-Fi and

Battery Power

The ultimate goal is to make

this piHPSDR controller completely wireless and portable. This should

be

doable. Using a 48KHz sampling rate, I can obtain good receive

performance, and transmit with an occasional garble, over an 802.11n

Wi-Fi connection. Testing with

iPerf3

finds my 802.11n connection capable of 6Mbytes/s, while the wired

100BASE-T connection is capable of 12Mbyte/s. Given others have been

successful in achieving greater than 12Mbyte/s on a Pi using 802.11ac,

I am confident I can use 802.11ac Wi-Fi to run the controller. To that

end I

have a D-Link DWA-171 802.11ac USB Wi-Fi adapter on order. This adapter

requires the installation of driver software to work, it will not work

with Raspbian out of the box.

I also have a 15000mA USB battery pack capable of sourcing 2A and am

waiting for delivery of

some 20AWG USB cables to test this battery pack with. If this

is successful then my piHPSDR controller will have achieved total

portability. More to follow!